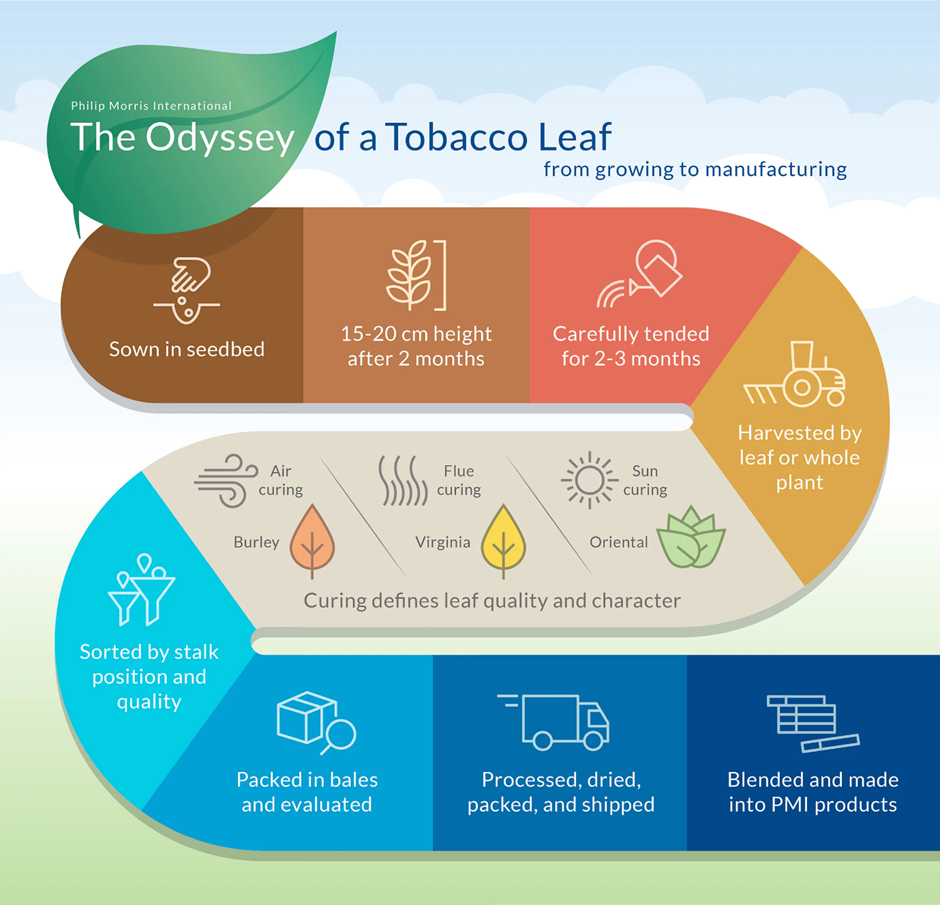

According to research of Phillip Morris International, the odyssey of Tobacco leaf is demonstrated as below picture:

This progress can be divided into 4 main phases:

- Firstly, tobacco growing

- Secondly, crop cultivating period includes seed sowing and tending for 2-3 months.

- Thirdly, harvesting then curing leaf to define its quality and character.

- Fourthly, sorting or granting and stabilizing leaf before manufacturing (drying, threshing, blending, tipping, conditioning, re-drying and packing) till making to cigarette.

Tobacco growing

The process of growing tobacco has not changed much in the last 200 years, although technology has been added to make production more efficient. The different stages of the process remain more or less the same.

The suppliers covers the entire tobacco growing process: planning the crops, selecting the right site with appropriate soil type and fertility, and preparing the land. This ensures that the tobacco has the best foundations for growth.

Crop cultivation

In the first stage of the growing process, tobacco seeds are sown in specially-constructed seedbeds. Selecting the right tobacco seed variety is essential to achieving a good yield of the desired quality of tobacco leaf. The seeds are sown in seedbeds (not too close together) to give each seedling enough room to grow.

Tobacco seeds are tiny – there are between 10,000 and 13,000 of them in a gram – and they germinate rapidly in five to ten days. Under the ideal seedbed conditions, they will grow to a height of 15-20 centimeters in about two months. They are then transplanted in the fields.

Harvesting

After two to three months, the plants are ready for harvesting. It is important to harvest precisely when the leaves are mature (or ripe) and in prime condition for curing.

Tobacco plants ripen from the bottom to the top. The farmers start harvesting Virginia tobacco by picking the early ripening leaves closest to the ground. They then move up the plant, picking the stalk layers as they ripen. Only three to six leaves are removed from the plant at each harvesting stage. Burley tobacco is normally harvested in a different way: farmers cut the whole plant and remove the leaves from the stalk after curing. Oriental tobacco leaves are harvested by hand, one by one, off of the plant as they ripen.

Curing

The curing of tobacco plays a major role in the final leaf quality, and it must be carefully controlled in order to bring out the characteristic taste of each tobacco type. Different types of curing are used for different types of tobacco.

Virginia tobacco is ‘flue-cured.’ The tobacco leaves are hung in curing barns, where heated air is generated to dry the leaves. As the leaves lose moisture, they develop their distinct aroma, texture, and color. The farmer must carefully guide this process, which takes up to a week, during which time the temperature of the heated air must be constantly monitored and gradually increased. Too much or too little heat at any stage of the process will have a negative impact on the quality of the tobacco. Burley and oriental tobaccos are cured differently.

Burley is ‘air-cured’ in barns where the heat and humidity come from natural ventilation. The curing process takes up to two months. Oriental tobacco is ‘sun-cured’ by hanging the leaves outdoors in the sun for about two weeks.

Grading and stabilizing to manufacturing

When the leaves have been cured, the tobacco farmer sorts them following to stalk position and quality, and packs them separately into bales for delivery to the point of sale. At the point of sale, the leaves are graded by expert leaf buyers who assess leaf quality by carefully checking variations in color, texture, and aroma.

Once the tobacco has been purchased, it is shipped to a local processing factory where the leaves are further processed and dried for uniformity. After the drying process, the tobacco is pressed into cases for shipment around the world.

Tobacco leaf may be stored for several years. The aging process helps to improve the flavor. After aging, the tobacco is moved to one of our manufacturing centers around the world, where it becomes part of the blends we use to manufacture our products.